The WarBird Manufacturing Center

Redefining the Standard

In 2025, WarBird transformed an 18,000-square-foot facility into a custom-engineered powerhouse specifically designed for the complexities of modern body armor production.

Every inch of this workspace is optimized for lean, one-piece flow and cellular work teams, ensuring that precision and efficiency coexist.

Cutting-Edge Precision

Our production floor features the industry’s most advanced technology to ensure life-saving consistency:

High-Ply Cutting

The brand-new KURIS high-ply system provides rapid, ultra-precise textile processing.

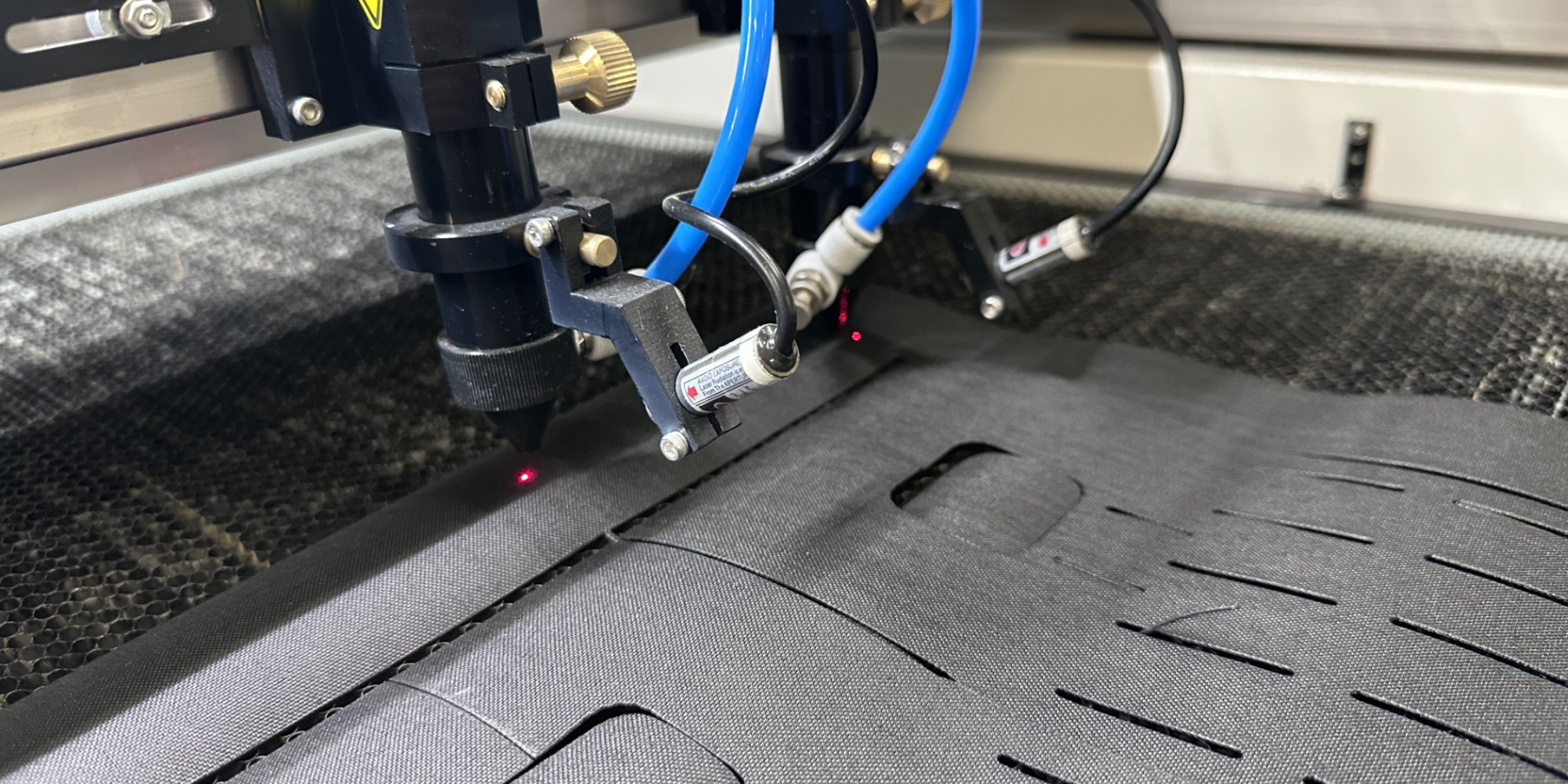

Advanced Laser Integration

Dual-head laser cutters engineered specifically for laminated fabrics and intricate load carriage systems.

Elite Sewing Labs

A dedicated environment equipped with top-tier Juki machinery, the gold standard for high-performance carrier assembly.

Integrated Innovation

We don’t just manufacture; we iterate. Our facility houses a Carrier Design Center alongside a state-of-the-art ballistics testing lab, allowing us to move from concept to certified protection under one roof.

Optimized Logistics

With an expansive raw materials warehouse and a flexible floor plan featuring multiple overhead doors, our facility is built for scale. We’ve eliminated bottlenecks to prioritize a seamless, agile supply chain.